Explore Hyperbaric Oxygen Chamber Materials

2025-01-06It has likewise undergone popular medical practice since it involves the use of HBOT for treating diseases starting from normal wound healing to even the condition known as Decompression Sickness otherwise known as divers’ bends. However, the materials that are used in the construction of a chamber of hyperbaric oxygenation provide very much safety, strength, and efficiency of therapy. In this article, we shall also look at the different types of hyperbaric oxygen chamber materials, pros, and safety measures as well as their influence on chamber performance.

What is Hyperbaric Oxygen Chambers?

A hyperbaric oxygen chamber is a controlled atmospheric pressure in which the patient breathes oxygen which helps the body to heal itself. These are chambers that are supposed to withstand pressure with a view of properly delivering oxygen to the body. The fabrication of these chambers has to be made out of materials that can address pressure-related issues including safety and biocompatibility.

Materials Used in Hyperbaric Oxygen Chambers

Stainless Steel, Polycarbonate, and SGS Certified High-Quality TPU in Hyperbaric Oxygen Chamber Materials

Hyperbaric oxygen chambers are specialist medical equipment designed for delivering high-pressure oxygen treatments for different illnesses. The construction materials they used are quite important so as to achieve the best durability and safety as well as performance. The most authentic ones are SS 316, polycarbonate, and SGS-authenticated superior quality TPU, also known as Thermoplastic Polyurethane. These materials possess exciting features that qualify them to be used in hyperbaric oxygen chambers.

Overview of Materials Used

Stainless Steel

Stainless steel is one of the most popular materials that can be used as the main construction material of hyperbaric oxygen chambers as a result of high strength, resistance to corrosion, and rather long service life. It has high pressure tolerance hence the stability of the chamber structure when it is in use for a long time. Stainless steel is also a very smooth, non-porous material, thus easy to operate and is easy to clean and maintain to facilitate the much-needed medical-grade hygiene.

Polycarbonate

Polycarbonate is a very strong material yet it is lightweight, preferred for the chamber’s transparent parts. It also has good impact strength and optical properties such that the users can peep into the chamber safely. It also does not crack when compressed and for this reason, it is applied where precision is of great importance, for instance, in observation windows.

SGS High-Quality TPU with Certification

Thermoplastic polyurethane (TPU) is also gradually being used more often in hyperbaric oxygen chambers’ construction due to its peculiarities. TPU has complied with international standards of quality, safety, and performance through SGS certification. TPU is very flexible and has good mechanical strength and pressure resistance, the material is ideal for seals, liners, and other internal elements of the chamber. They include biocompatibility and chemical resistance which makes it ideal for use in medical scenarios.

Pros of Stainless Steel, Polycarbonate, and TPU on Hyperbaric Chambers

Durability and Longevity

Stainless Steel: The stainless steel used in the design has an exceptional tensile strength and it resists corrosion which enables the chamber’s structure to be well built to withstand pressures and humid conditions.

Polycarbonate: It also features high impact resistance that makes breaks and cracks in the observation windows as well as other clear parts minimal hence helping to increase their lifespan.

TPU: TPU is flexible and very hardy in nature so it is capable of standing pressure multiple times without getting compromised.

Safety and Reliability

Stainless Steel: Its structural design helps to control the chances of structural failure hence making sure the chamber works as intended.

Polycarbonate: It is impact-resistant and thus safer than glass, in case of accidents, it will not cause harm to people around.

TPU: TPU has gained international certification from SGS which ensures biocompatibility and resistance to chemicals for its products.

Lightweight Design

Compared with traditional materials, the integration of polycarbonate and TPU greatly decreases the total weight of the hyperbaric chamber. This makes transportation, installation, and handling easier unlike the conventional equipment but with equal efficiency.

Maintenance and Hygiene

Stainless Steel: It has a relatively smooth outer side that can be easily sterilized, beneficial in keeping high medical standards.

Polycarbonate: The material does not allow the development of bacteria to penetrate since it is non-porous thus ensuring a cleaner environment is maintained in the medical facilities.

TPU: Styling to chemical cleaners, TPU components are easy to maintain, and stringent measures are adopted to ensure the TPU components remain clean and usable over the long run.

Performance under Pressure

Stainless Steel: Resists high pressures without deformation of the vessel.

Polycarbonate: Keeps much organization and firm construction where there are high-stakes pressure settings.

TPU: Attaches well for flexibility and does not leak even when under consistent pressure.

Why These Materials Matter?

In hyperbaric oxygen chambers, stainless steel, polycarbonate, and SGS-certified TPU means that the medical devices work effectively, are as safe as possible, and reliable. The use of these materials in unison provides an excellent strength coupled with flexibility, not forgetting the easy maintenance that these components require; features that are very applicable in medical equipment. From the manufacturer’s side as well as from the side of users, these high-quality materials not only increase the durability and reliability of hyperbaric chambers but also meet international requirements. Stainless steel offers a rigid bearing while the polycarbonate offers high clarity and durability and the TPU which has high flexibility and safety are some of the most beneficial materials in hyperbaric oxygen chamber performance.

Key Considerations When Choosing Materials for Hyperbaric Chambers

Pressure Vessel Materials

Hyperbaric oxygen chambers by their design are pressure vessels that must be capable of containing a high internal pressure. The materials used to construct pressure vessels have to withstand a constant force within them in failure and crack formation.

Oxygen-Compatible Materials

Since oxygen is the basis of therapy, the fabrics selected should be compatible with oxygen. Substances that are incompatible with oxygen cause fires or in extreme cases affect the physical characteristics of the material. The selected materials must not be compromised when oxygen is present in high concentrations as such.

Accident Prevention and Risk Control

Every hyperbaric oxygen chamber has to provide appropriate safety conditions as prescribed by the corresponding authorities, for example, FDA or ISO. Hyperbaric chamber material safety standards are in place designed to prevent harm to patients where combustibility, toxicity of the chamber parts, and its ability to withstand fatigue are factors.

Biocompatibility and Non-Toxicity

There is therefore a need for advancing the materials used, to be as biocompatible as possible to reduce dangers faced by the patient. They should not emit toxic substances when placed under pressure, or when used to perform their function in therapy. This is especially important if the composite material being used is fiberglass or composite materials that undergo some form of a chemical treatment that may have adverse reactions with oxygen.

Conclusion

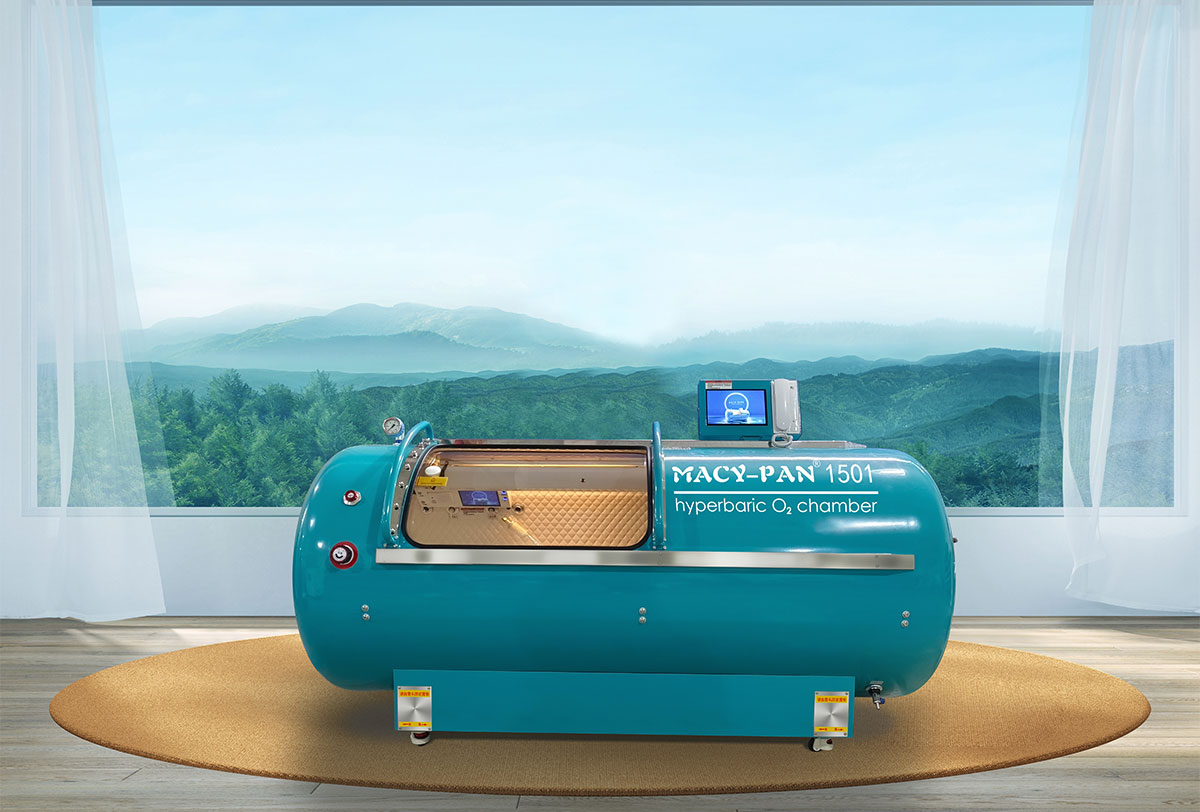

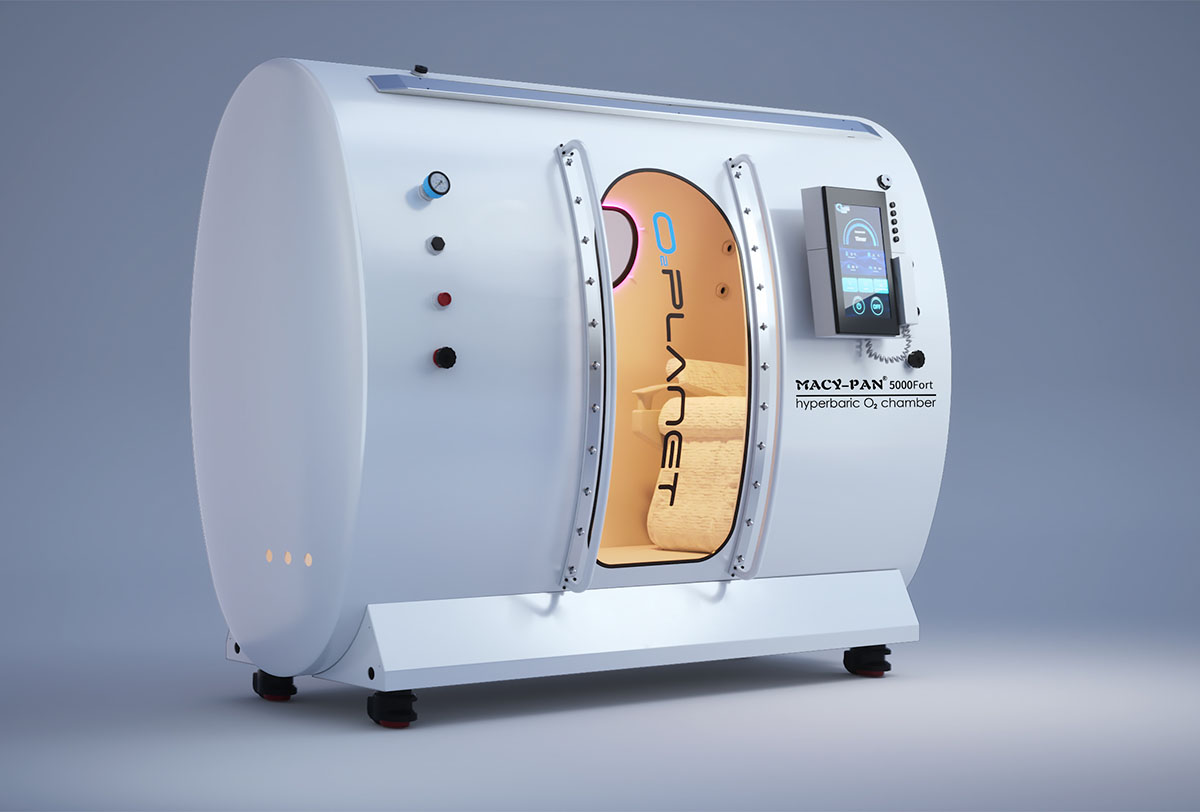

The materials used in hyperbaric oxygen chambers are integral to their performance, safety, and longevity. Whether you are considering acrylic, fiberglass, steel, aluminum, or composite chambers, each material offers unique advantages. For further information on hyperbaric oxygen chamber construction, safety regulations, and materials, you can visit trusted resources like Macy Pan, where we specialize in providing high-quality chambers made with the best materials to ensure patient safety and therapy effectiveness.

Hey, I’m Macy-Pan

1# Hyperbaric Oxygen Chamber Manufacturer in China. 18 years of industry experience. 126 countries and regions reached